Over 30 years of industry experience

A fully bespoke service

In house professional delivery service

Space Joists & Spandrel Panels

Space Joists and Spandrel Panels

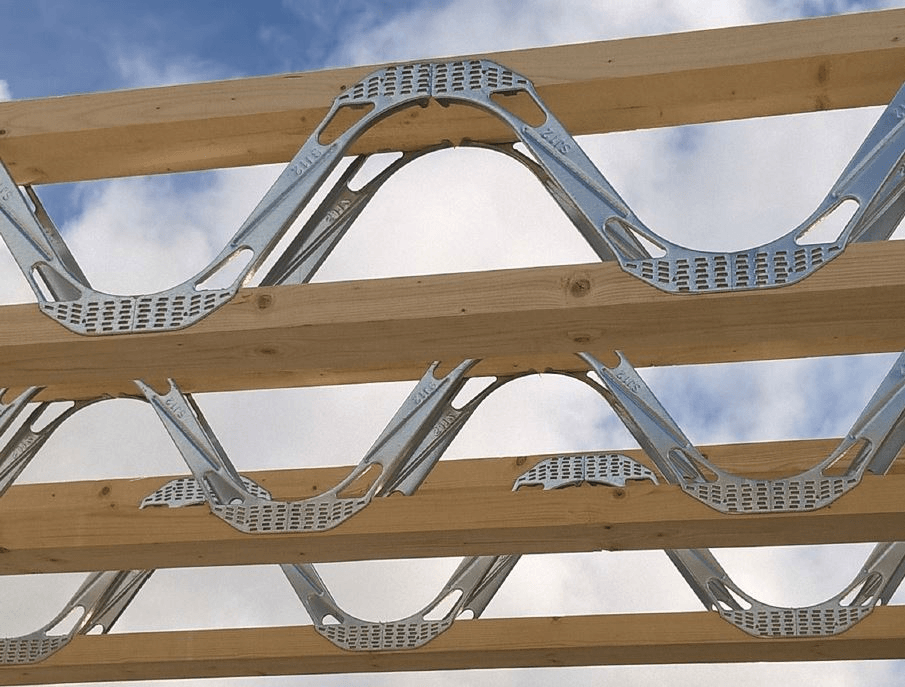

Made from stress graded timber, our panels consist of timbers which are joined together using metal web joists. They are available in a range of sizes and can be cut to your exact specifications. Whether it is a small domestic project or large housing development, we can provide a cost-effective solution.

Benefits of Space Joists

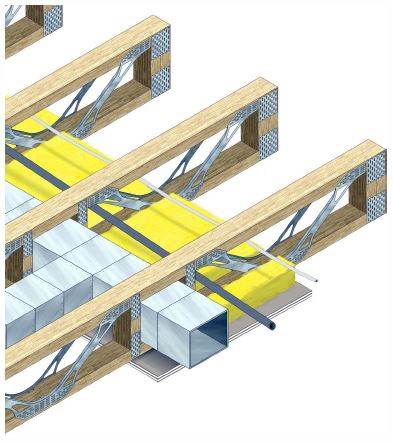

Space joists have many advantages over timber engineered joists. We manufacture all our joists to strict tolerances and specific designs to give the most economical but structurally sound floor. We provide full on site detailed drawings to ensure the fitting time is kept to a minimum.

- Long spans are achievable which may eliminate intermediate load bearing walls, thus reducing a building’s overall cost.

- Reduced wastage: Manufacturing to size eliminates site alterations saving site time.

- Design flexibility: Space joists can be designed top hung to eliminate the rim board, decreasing the risk of timber shrinkage to improve air tightness.

- Sound performance: Outstanding acoustic performance to comfortably pass English and Welsh regs, even complying with the more stringent 43dB Scottish regs without additional insulation, plasterboard or resilient bars.

- Easy to handle: A lightweight construction makes space joists easy to individually manhandle. Alternatively, floor and roof sections (cassettes) can be delivered and craned into position to save build time.

- Wide nailing surface for easy fixing of floor and ceiling materials

- Engineered: Manufactured offsite ensuring consistent quality and reliability.

- Open web design for easy installation of services, without drilling or notching, accommodating large services such as Mechanical Heat Recovery Systems.

- Home grown timber can be used in manufacture – reducing carbon footprint.

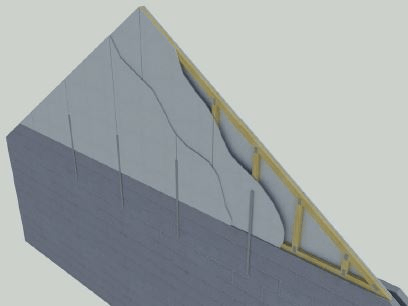

Spandrel Panels

Spandrel panels are becoming increasingly popular with house builders and self builders. They consist of a non-structural panel which replaces the internal blockwork of a gable end/or party wall.

Spandrels can be manufactured as a simple frame with OSB sheathing on the outer face or clad with 1 or 2 sheets of plasterboard to create fire protection. Spandrel panels can also be ore insulated when they are used in an attic roof.

The benefits of spandrel panels:

- Quicker erection time - Installing a pre manufactured spandrel panel will save hours of bricklaying time. There is also no requirement for waiting for blockwork to cure before roof insulation.

- Safety - By speeding up the erection time of the gable end means less time is spent by workers at height reducing the risk of falls and accidents.

- Cost Saving - Using spandrel panels can eliminate the need for roof trusses at the gable wall as tiling laths and ceiling plasterboard can be more easily fixed to the timber frame structure than a traditional blockwork gable. Scaffolding costs are also reduced.

- Single trade solution - Using a single trade to manufacture roof trusses and spandrel panels saves the need to liaise with multiple trades and guarantees accuracy in lining through.

Need timber joists for your project? Send an email to

Phone: 01302 820320

Email: enquiries@sytruss.co.uk

Address:

Millfield Ind Est, Bentley

Doncaster

DN5 0SJ

© 2025. The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.